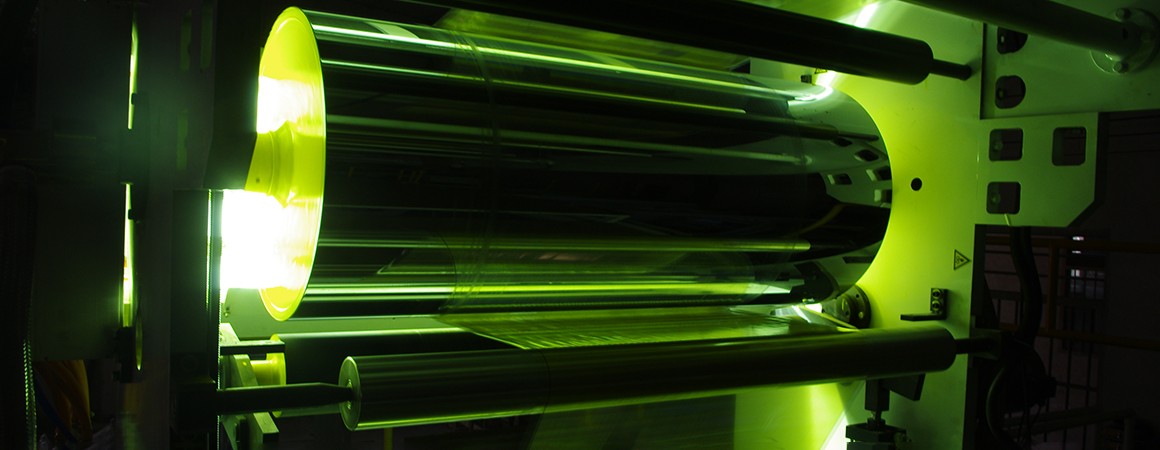

Our UV Curable Acrylic Warm Melt adhesive technology is a new adhesive platform that enables the deployment of high-performance acrylic polymer technology across a broad range of pressure-sensitive applications. UV Curable Acrylic Warm Melt is an alternative to typical water- or solvent-based adhesives, which contain about 50% water by weight, or organic solvent that must be removed during the coating and drying processes. Our new adhesive platform contains no water or solvent, eliminating the need for the energy-intensive drying and thermal oxidation processes. Since it cures with lamps instead of ovens, the coating reduces the total energy required to produce a coated product by more than half, dramatically reducing related greenhouse gas emissions. The absence of solvents means near-zero emissions of volatile organic compounds (VOCs) and little to no residual VOCs in the final product. This makes it a preferable solution for automotive, food, and medical applications. Because UV Curable Acrylic Warm melt is composed of 100% solids, it lowers freight impact by about 60% compared to water- or solvent-based adhesives. With these significant processing and environmental advantages, adhesives based on the UV Curable Acrylic Warm Melt platform have the potential to significantly reduce consumption of both solvents and energy.

.png)